The Atomic Force Microscope has many applications in the Optics and Photonics Industry

Diffraction Gratings

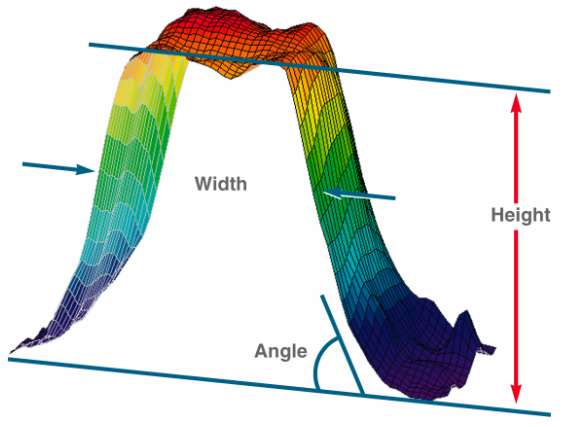

The performance of diffraction gratings is dependent on precise control of the size and shape of the features and on their consistent, regular spacing. AFM provides a tool for measuring that directly.

Our tool DiscTrack Plus can be used to automatically measure the size, shape, and position of features in AFM images of diffraction gratings. By automating the measurement process DiscTrack Plus allows measuring large numbers of features for good statistical results while still maintaining the ability to examine individual features.

measured at multiple levels in the feature and the angle is measured

in both sides.

Another parameter that may be important to diffraction grating performance is line edge roughness. DiscTrack Plus measures this too.

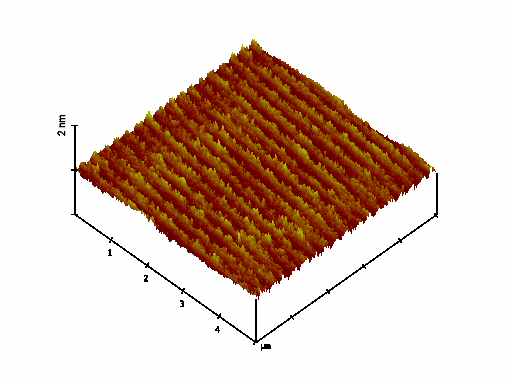

Superpolished optics and other precision surfaces

As optical engineering moves into the shorter wavelengths, the far ultraviolet and X-ray regimes, the smoothness of optical surfaces becomes increasingly critical. AFM provides a direct measurement of the surface roughness at the micron to nanometer scale.

atomic steps. AFM can measure roughness down to the

atomic level to speed the development of precision optics

including grazing incidence X-ray optics.